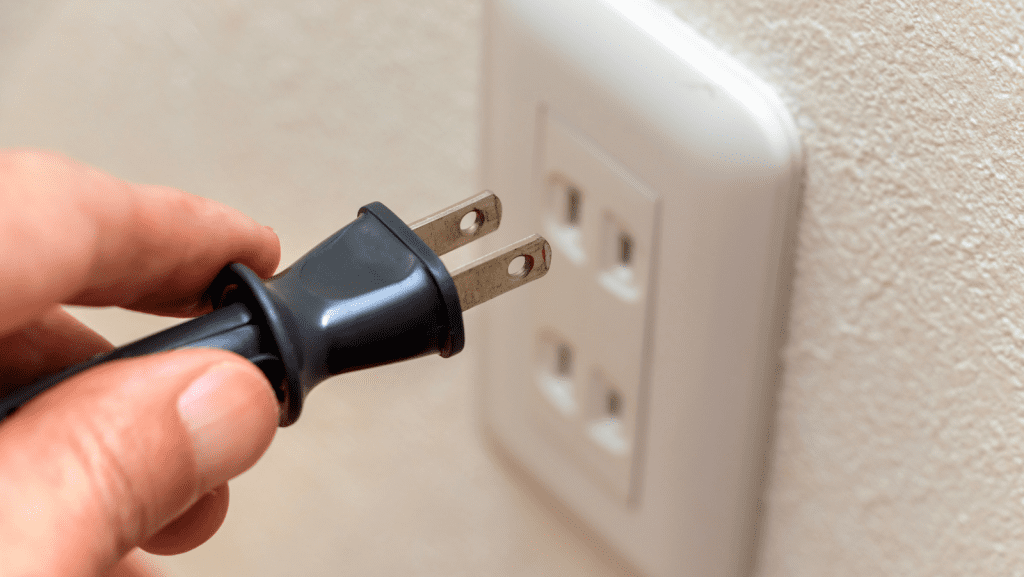

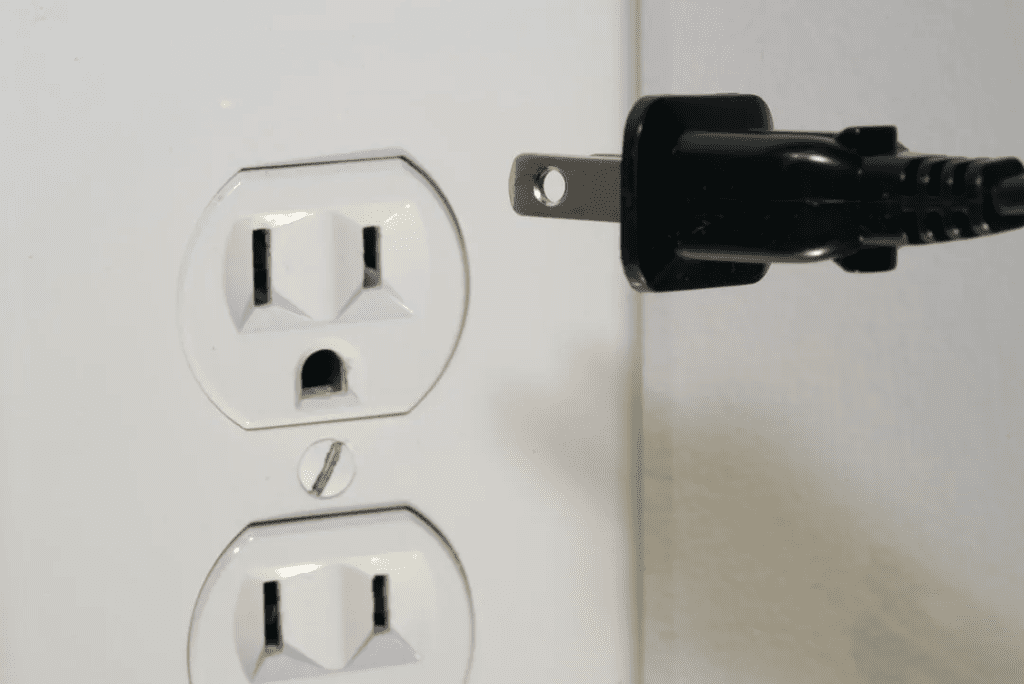

Electrical plugs are something we use every day without a second thought. But have you ever wondered why some plugs have two small round holes on the prongs? These seemingly insignificant details actually play a crucial role in enhancing plug stability, improving safety, and optimizing manufacturing processes. In this article, we’ll explore the hidden magic behind these two holes and why they matter.

Enhancing Stability with Innovative Features

When you plug an electrical device into an outlet, you want it to stay securely in place. This is where the two round holes on the prongs come in.

1. Better Connection for Stable Power Flow

The holes in the prongs align with a raised metal piece or locking mechanism found inside most outlets. When inserted, these metal pieces fit into the holes, creating a tighter grip on the prongs. This enhanced connection ensures that the prongs make consistent contact with the metal strips inside the socket. As a result, the plug remains firmly in place, reducing the risk of it becoming loose or disconnected unexpectedly.

2. Why Stability Matters

A secure fit means a steady and reliable flow of electricity to your device, preventing issues such as flickering lights or intermittent power loss. For electronic devices that require a stable power source, this feature is crucial for maintaining performance and avoiding disruptions. Plus, a plug that fits securely is less likely to slip out accidentally, reducing the need for constant adjustments.

Promoting Safety and Preventing Accidents

Safety is a top priority in electrical design, and the holes on your plug’s prongs play a surprising role in accident prevention.

1. Reducing the Risk of Accidental Disconnection

When a plug is securely in place, it’s less likely to be accidentally pulled out. This is particularly useful in environments where children are present or in spaces where plugs could be accidentally bumped or knocked loose. By keeping the plug steady, the two holes help ensure that power delivery remains consistent and prevent dangerous situations, such as sparks or exposed metal prongs.

2. A Safety Measure for Households with Children

These holes also serve an additional safety purpose: they reduce the likelihood of accidental shocks. In many cases, these holes make it more difficult for curious fingers, especially those of young children, to come into contact with the live prongs. Some outlets even include locking mechanisms that grip the holes and make it more challenging for anyone to remove the plug without a bit of effort.

Choosing the Right Plug Type for Families

For households with children, safety considerations extend beyond outlet covers and childproofing kits. The design of your plugs themselves can make a difference.

1. Flat-Pronged Plugs with Securing Holes

While some plugs feature round prongs, these may not fit as securely into outlets. This can leave part of the prong exposed, which can be a safety concern for young children who may be tempted to touch it. Flat-pronged plugs with securing holes are a safer alternative because they fit more snugly into the outlet, minimizing exposed metal and enhancing the grip. For families with children, choosing plugs with these safety features can add an extra layer of protection.

2. Understanding Plug Compatibility

Not all outlets are compatible with plugs that feature holes in the prongs. Therefore, it’s important to know what type of outlets you have in your home. If you’re considering upgrading your outlets, look for child-safe designs that work with these plugs to provide a more secure fit. In addition, always ensure that your outlets are up to date with safety standards and are in good condition, as outdated outlets can compromise both safety and functionality.

Manufacturing Insights: Efficiency and Identification

Believe it or not, the two holes on plug prongs also serve practical purposes in manufacturing. These small details can make a significant difference when it comes to production and quality control.

1. Streamlining the Production Process

Manufacturers use these holes to facilitate certain production processes. During assembly, the holes allow machinery to hold onto the prongs more easily, making it simpler to assemble and position components accurately. In mass production, this feature can enhance efficiency and reduce the likelihood of errors, ultimately leading to better quality control.

2. Quality Control and Consumer Confidence

In some cases, these holes are used to apply seals or markings that indicate whether a product is new or has been tampered with. This helps manufacturers maintain quality standards and reassures consumers that they are purchasing a safe, reliable product. For example, if you notice a missing or broken seal on a plug, you may want to think twice before using it, as this could indicate that the plug is damaged or unsafe.

Material Efficiency: A Cost-Effective Design Choice

One of the often-overlooked advantages of the holes in plug prongs is their contribution to material efficiency. By incorporating these holes into the design, manufacturers can reduce the amount of metal needed to produce each prong, which translates to significant savings over large production runs.

1. Reduced Material Usage Without Compromising Quality

Using less metal per prong may not seem like a big deal on an individual level, but when multiplied by millions of units, this slight reduction can result in substantial cost savings. Furthermore, these savings don’t come at the expense of quality or durability. The two holes in the prongs actually enhance the plug’s function by providing a secure fit, demonstrating that even small design choices can have a big impact.

2. Environmentally Friendly Manufacturing

Reducing material usage is not only cost-effective but also environmentally friendly. By using less metal, manufacturers can decrease their overall environmental footprint, minimizing waste and conserving resources. In an era where sustainability is a growing concern, design features that contribute to both function and eco-friendliness are more valuable than ever.

Enhancing Consumer Awareness: Why It Matters

Understanding the function of the two round holes on your plug’s prongs can make you a more informed consumer. By recognizing the purpose behind these seemingly minor details, you can make smarter choices when selecting electrical products and better appreciate the safety features that protect you and your family.

1. Knowing What to Look for in Electrical Products

When shopping for electrical devices, consider features that enhance both safety and functionality. Plugs with securing holes offer a more stable connection, which can improve the overall performance of your devices. If you have children or are particularly safety-conscious, look for products with these features, as they are designed with accident prevention in mind.

2. The Power of Small Design Choices

The design of everyday items, like electrical plugs, often goes unnoticed, yet these small choices can have a significant impact. By understanding the purpose of the holes in plug prongs, you gain insight into how thoughtful design can enhance safety, efficiency, and sustainability. This awareness empowers you to make better decisions for your home and family, helping you choose products that prioritize both quality and safety.

Conclusion: The Hidden Magic in Everyday Objects

The next time you plug in an appliance, take a moment to appreciate the small details, like the two round holes on the prongs. These holes are more than just a design quirk—they play a vital role in enhancing plug stability, improving safety, and supporting efficient manufacturing. By understanding these features, you can become a more knowledgeable consumer, making choices that prioritize safety, sustainability, and functionality.

In a world where we often overlook the details, the story of the humble plug reminds us that even the smallest features can hold hidden magic. So, the next time you reach for an outlet, remember the role these tiny holes play in keeping your devices, and your home, running smoothly.