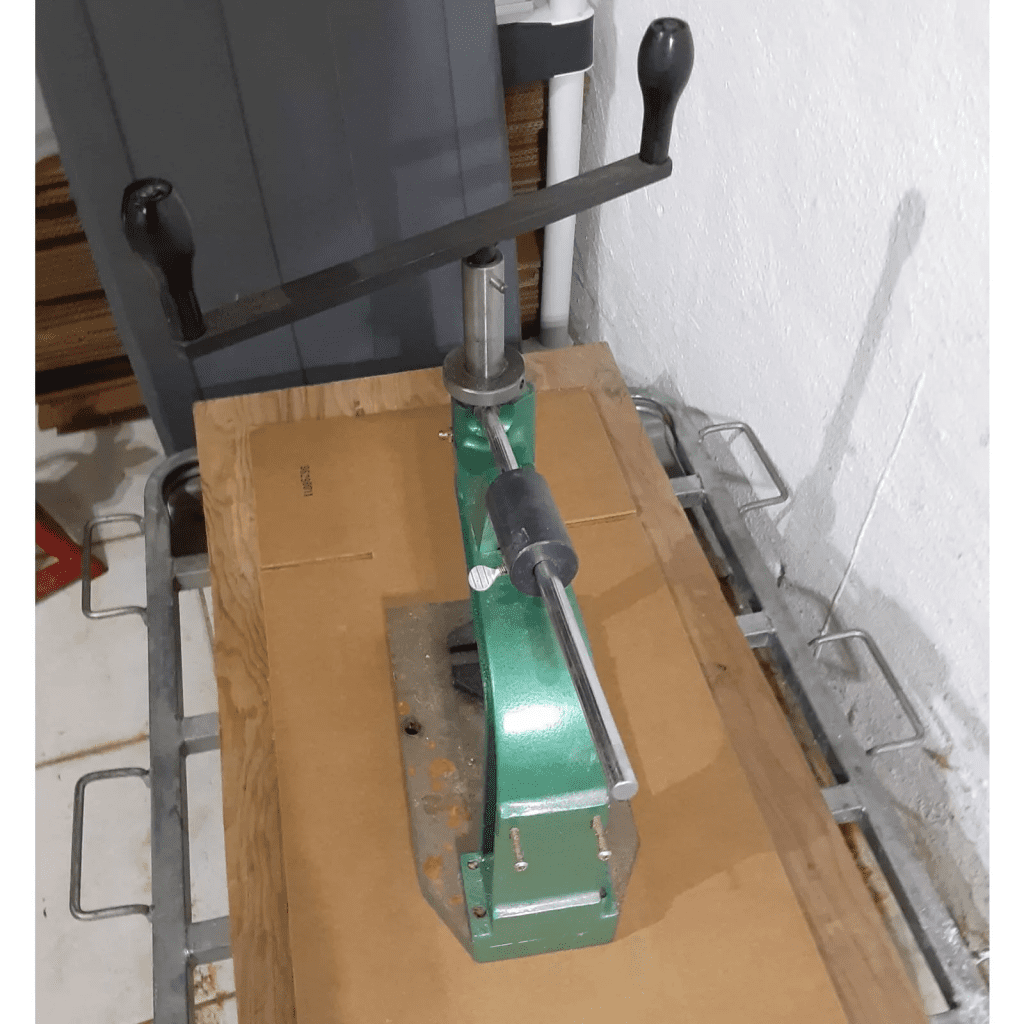

The vintage hand tapping machine stands as a timeless piece of industrial engineering, showcasing the evolution of precision tools in manufacturing. With its manual operation and meticulous design, this machine was once a cornerstone in various industries. Its role in producing fine threads in materials like metal and wood paved the way for the efficiency we see in modern-day machinery. This article explores the history, usage, and legacy of the vintage hand tapping machine and its enduring impact on the world of craftsmanship.

A Glimpse into History: The Birth of the Hand Tapping Machine

The hand tapping machine emerged during a period of rapid industrial growth, specifically in the late 19th and early 20th centuries. This era marked a shift in manufacturing, where the demand for precision and efficiency drove the development of more specialized tools. The hand tapping machine was born out of necessity, allowing machinists and craftsmen to create threaded holes manually—an essential process for assembling parts in burgeoning industries like automotive, aerospace, and construction.

Initially, hand tapping machines were simple in design, built to withstand the rigors of daily use in small workshops and factories. As time went on, their design evolved with better materials and mechanisms, increasing both durability and accuracy. These machines became more refined, allowing operators to produce consistently high-quality threaded holes, which were critical for the proper assembly of components.

How the Hand Tapping Machine Revolutionized Industrial Processes

The primary function of a vintage hand tapping machine was to create threaded holes in various materials, such as metal, wood, and plastics. This was a meticulous process that involved manually driving a tap (a tool used to cut threads inside a hole) into a workpiece. Operators would carefully turn the handle of the machine to ensure precision, as even a minor error could compromise the integrity of the final product.

Precision and Control

Unlike modern, automated machines, the hand tapping machine required a skilled operator who could manually adjust the speed and pressure to suit the material being tapped. This level of control allowed machinists to create intricate threads with remarkable accuracy, making the machine highly valued in industries where precision was critical. Whether it was for assembling parts in an engine or securing components in a structural framework, the hand tapping machine provided the reliability that modern industry demanded.

The Versatility and Adaptability of the Hand Tapping Machine

One of the key strengths of the vintage hand tapping machine was its versatility. These machines could be adapted to accommodate a wide range of materials and thread sizes, making them invaluable in diverse manufacturing settings. From small, delicate parts to larger industrial components, the hand tapping machine could handle various tasks with ease.

Craftsmanship Meets Functionality

Machinists and craftsmen appreciated the machine’s ability to offer precise adjustments, allowing them to customize threads for specific applications. Whether it was creating threads in a soft material like wood or a more challenging substance like steel, the machine’s manual operation gave artisans a sense of control that is often lost in today’s automated processes. This adaptability contributed to its widespread use across multiple industries.

The Decline and Legacy of the Vintage Hand Tapping Machine

As technology advanced, automated tapping machines and CNC (Computer Numerical Control) systems gradually replaced the manual hand tapping machine. These modern innovations offered increased speed and efficiency, eliminating the need for human intervention in many instances. However, the vintage hand tapping machine’s impact on the evolution of industrial tooling cannot be overstated.

A Symbol of Industrial Ingenuity

Though largely obsolete in today’s fast-paced industrial world, the vintage hand tapping machine remains a symbol of craftsmanship and ingenuity. These machines represent a time when skilled labor was paramount, and every turn of the handle required focus and expertise. They are a reminder of the hands-on approach that once dominated manufacturing, where the precision of the final product depended largely on the operator’s skill.

Today, vintage hand tapping machines are prized by collectors and enthusiasts, many of whom showcase these tools in museums and private collections. The machines are appreciated not only for their functional contributions to industrial history but also for their aesthetic appeal and engineering excellence. Their robust construction, often featuring ornate designs and high-quality materials, make them fascinating relics of a bygone era.

The Role of Hand Tapping Machines in Shaping Modern Manufacturing

While modern machines have largely taken over the role once played by hand tapping machines, their influence remains apparent in today’s tools and methods. The craftsmanship, precision, and versatility that characterized these machines continue to inspire modern engineers and machinists.

Inspiration for Today’s Innovations

Many of the principles behind the hand tapping machine’s design—such as accuracy, manual control, and adaptability—have been integrated into modern manufacturing technologies. The meticulous attention to detail that these machines demanded of their operators has set a standard for today’s CNC machines and automated processes, which strive to replicate the same level of precision on a larger, faster scale.

Even though hand tapping machines have become a part of history, their legacy endures in the world of industrial engineering. The blend of skill and technology that these machines represented continues to influence the way we think about manufacturing tools and processes today.

Conclusion: Celebrating the Legacy of the Vintage Hand Tapping Machine

The vintage hand tapping machine is more than just a piece of industrial equipment; it is a testament to the craftsmanship and innovation that defined early manufacturing. From its humble beginnings in small workshops to its critical role in major industries, the hand tapping machine has left an indelible mark on the world of engineering.

Its history highlights the evolution of manual tools and the important role they played in shaping modern industry. While the world has moved on to more advanced technologies, the legacy of the hand tapping machine continues to inspire engineers and machinists who value precision and craftsmanship. Whether admired as a collectible or studied for its engineering ingenuity, the vintage hand tapping machine remains a symbol of a time when the skill of the operator was as important as the tool itself.