In the early days of industrialization, as machinery and engines began taking over industries, a small yet vital tool emerged to meet the rising demand for precision and reliability: the gasket cutter. Though seemingly modest, the vintage gasket cutter played a crucial role in the development of mechanical systems, ensuring machines operated without leaks and functioned efficiently. This article explores the origins, evolution, and lasting impact of the vintage gasket cutter and its inspiration for both collectors and modern industries today.

The Origins of the Vintage Gasket Cutter

The origins of the vintage gasket cutter date back to the early 20th century, during the height of the industrial revolution. As engines and other mechanical systems became increasingly complex, the need for tools that could create precise gaskets grew significantly. These gaskets were essential components that created tight seals between machine parts, preventing leaks and ensuring smooth operations. In this era, with no automated solutions, hand-operated tools like the gasket cutter were invaluable.

Why Gasket Cutters Were Needed

With industries such as automotive, aviation, and manufacturing rapidly expanding, there was a growing reliance on machines with intricate components. These components needed tight seals to prevent fluid leaks, such as oil, water, and gas. Gaskets made from materials like rubber, cork, leather, and fiberboard offered the solution, and machinists required a tool to create custom gaskets of various sizes and shapes.

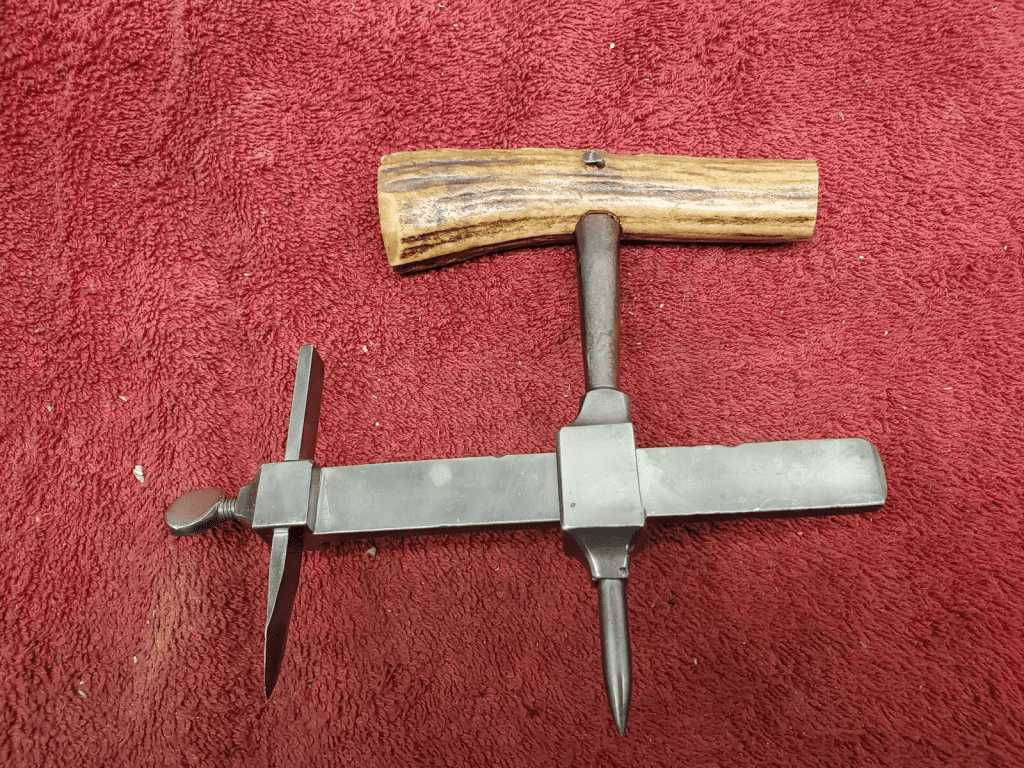

The vintage gasket cutter was designed for portability and versatility. Featuring an adjustable blade attached to a central pivot, it allowed machinists to create perfect circles in various materials. This design enabled workers in factories, workshops, and home garages to craft custom gaskets for engines, valves, pumps, and plumbing systems.

The Evolution of the Gasket Cutter in Manufacturing

As industries evolved, so did the gasket cutter. Initially, these tools were purely mechanical, relying on the operator’s skill and precision. Users would adjust the cutting radius to match the required gasket size and carefully cut through the material. This manual process required steady hands, keen attention to detail, and manual force to ensure the gasket fit perfectly and created a secure seal.

Usage Across Key Industries

The vintage gasket cutter was crucial in industries where precision was paramount. In the automotive industry, for instance, gaskets ensured engines operated efficiently without leaks. Similarly, in aviation and heavy manufacturing, the integrity of seals in machinery components was directly linked to safety and performance. The ability to produce custom gaskets on demand, for either a factory assembly line or a small workshop, made the gasket cutter indispensable.

Beyond industrial settings, hobbyists, mechanics, and small-scale machinists found the vintage gasket cutter reliable for repairing engines and machinery. Unlike large manufacturing tools, the gasket cutter was compact, affordable, and required no complex training. It allowed individuals to create precise, circular gaskets for a wide range of mechanical systems.

Craftsmanship: The Heart of the Vintage Gasket Cutter

What set vintage gasket cutters apart from modern tools was the emphasis on craftsmanship. In an era before computerized automation, precision came from skilled human hands. Operators needed to be adept craftsmen, capable of adjusting the tool’s radius perfectly, applying the right pressure, and ensuring a clean, circular cut each time.

Manual Precision in a Machine-Driven World

The appeal of the vintage gasket cutter lies in its embodiment of manual craftsmanship during the rise of machine-driven industries. While machines grew more sophisticated, the gasket cutter symbolized the ingenuity and skill required to maintain and repair these machines. It became a testament to human expertise in an increasingly mechanized world.

The Transition to Modern Gasket Cutting Methods

As technology advanced, so did gasket creation methods. Today, computerized CNC machines and laser cutters have largely replaced manual tools like the vintage gasket cutter. These modern automated systems can produce gaskets with incredible precision, efficiency, and consistency, far beyond what hand-operated tools could achieve. Factories now rely on software-driven systems to create gaskets en masse, reducing time and labor.

From Hand Tools to Automation

Although automation has made gasket production faster and more efficient, the vintage gasket cutter still holds a place in many workshops and industries. For those who value customization, repair work, and nostalgia, the hand-operated gasket cutter continues to serve a purpose. It allows for quick, on-the-spot gasket creation, especially in situations requiring custom sizes or specific materials.

Legacy and Modern Impact of the Vintage Gasket Cutter

While the era of hand-operated gasket cutters may have passed, their legacy continues to influence modern industries. Collectors, tool enthusiasts, and industrial historians hold these tools in high esteem for their role in shaping 20th-century manufacturing processes.

The Role of Vintage Tools in Collecting and Restoration

Today, vintage gasket cutters are sought after by collectors and restoration experts. Often found in antique shops or industrial auctions, these tools are admired for their craftsmanship, durability, and historical significance. Collectors view them as artifacts from an era of industrial innovation, restoring and preserving them as part of their collections.

Moreover, the vintage gasket cutter has inspired modern manufacturers to continue focusing on precision and quality in tool design. While most gasket cutting is now automated, creating custom solutions remains a priority in industries where precision is critical.

Conclusion: The Enduring Symbol of the Vintage Gasket Cutter

The vintage gasket cutter stands as a symbol of craftsmanship, innovation, and the hands-on expertise of early 20th-century machinists. Its role in producing custom gaskets for industrial machinery helped forge the path for modern mechanical systems. While largely replaced by automated methods, the legacy of the vintage gasket cutter endures, reminding us of the importance of skill and precision in manufacturing.

As a tool that was once essential in factories, workshops, and home garages, the gasket cutter’s contribution to industrial progress cannot be overstated. Whether admired as a collectible or remembered for its practical applications, the vintage gasket cutter continues to inspire respect for the art of machine maintenance and the craft of mechanical repair.