Dovetail jigs are indispensable tools in the woodworking world, known for their ability to create strong, precise joints that stand the test of time. With origins rooted in traditional joinery, these jigs have undergone significant evolution, making them invaluable for both amateur and professional woodworkers alike. Let’s dive into the fascinating world of dovetail jigs, exploring their history, usage, and enduring impact.

Historical Background of Dovetail Jigs

The dovetail joint is a technique that dates back thousands of years, with evidence found in ancient Egyptian furniture and Chinese woodworking artifacts. Skilled artisans embraced this joint for its exceptional strength and resistance to pulling apart. However, crafting dovetail joints by hand required considerable skill, time, and precision—qualities that not every woodworker possessed.

Fast forward to the late 20th century, and the introduction of dovetail jigs transformed the woodworking landscape. These innovative tools allowed even novice woodworkers to achieve the precision of traditional joinery without extensive training. Early jigs, often made from metal, utilized templates and guides to assist users in cutting the necessary angles and shapes, making it easier to create flawless joints.

How Dovetail Jigs Work

Using a dovetail jig streamlines the process of crafting these iconic joints, making them accessible to a broader audience. Here’s how it works:

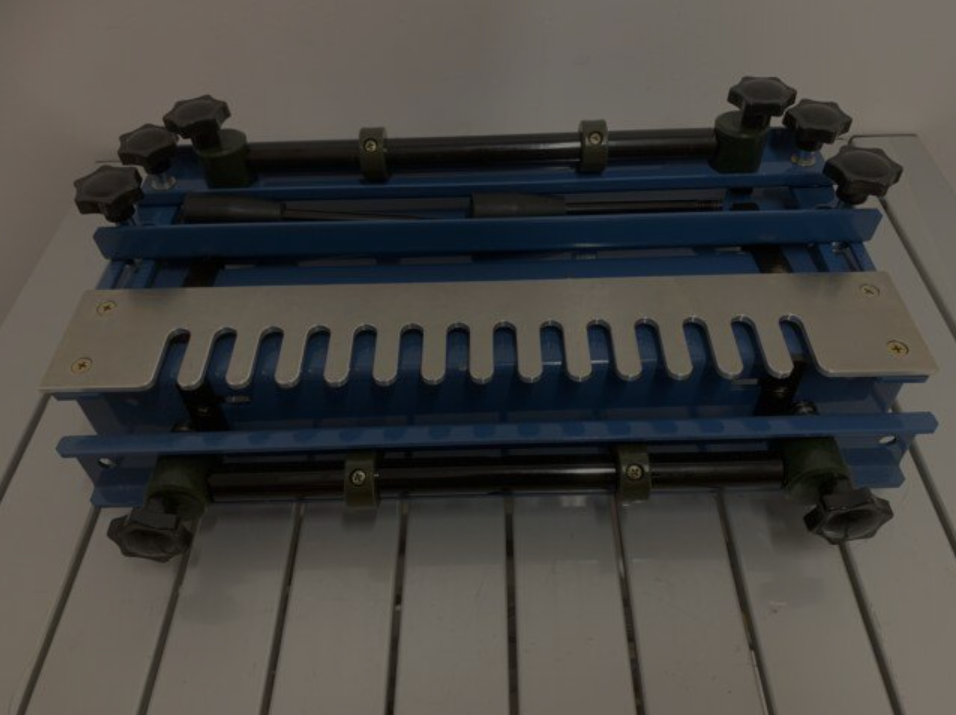

- Set Up the Jig: Users adjust the jig to accommodate the wood thickness and the type of joint they want to create—be it through, half-blind, or sliding dovetails.

- Secure the Wood: The jig holds the wood securely, preventing any movement during the cutting process.

- Cutting the Joint: With the jig in place, users can cut the joint using a router or saw, ensuring accuracy and repeatability.

This straightforward setup not only saves time but also significantly enhances the quality of the finished product.

Common Applications of Dovetail Jigs

Dovetail joints are celebrated for their strength and aesthetic appeal, making them a popular choice in various woodworking projects. Here are some common applications:

- Furniture Making: Dovetail joints are widely used in constructing drawers, cabinets, and casework. Their robust design ensures longevity, while their visual charm adds character to furniture pieces.

- Cabinetry: Whether you’re building a kitchen cabinet or a custom wardrobe, dovetail jigs are essential for creating durable and visually appealing joints that stand out.

- Woodworking Projects: Hobbyists and professionals alike utilize jigs for various projects, from intricate boxes to complex furniture. These tools enhance craftsmanship and skill, allowing woodworkers to explore their creativity.

The Legacy of Dovetail Jigs

The legacy of dovetail jigs lies in their power to democratize woodworking. They have enabled countless individuals to create professional-quality pieces, fostering a deeper appreciation for craftsmanship. As woodworking technology continues to evolve, dovetail jigs remain relevant, adapting to new tools and methods while retaining their core function.

Moreover, these jigs have opened doors for those who may not have had the opportunity to learn traditional woodworking techniques. By making it easier to achieve high-quality results, dovetail jigs have inspired a new generation of woodworkers to explore the craft.

Cultural Impact of Dovetail Jigs

In the woodworking community, dovetail jigs symbolize precision and quality. They frequently appear in workshops and educational settings, emphasizing their importance in skill development. The ability to produce strong joints efficiently has influenced contemporary design, encouraging woodworkers to tackle more intricate and ambitious projects.

Additionally, dovetail jigs have found a place in woodworking education, where they serve as essential teaching tools. They help aspiring woodworkers grasp the fundamentals of joinery, making the learning process both engaging and rewarding.

The Enduring Importance of Dovetail Jigs

Dovetail jigs exemplify the beautiful blend of tradition and innovation in woodworking. From their historical roots in joinery to their modern applications, these tools have made a lasting impact on the craft. As woodworkers continue to explore new possibilities and push the boundaries of their creativity, dovetail jigs will undoubtedly remain a staple in workshops around the world.

By facilitating the creation of strong, precise joints, dovetail jigs embody the spirit of craftsmanship, allowing woodworkers to express their artistry while honoring a rich tradition. Whether you’re a seasoned pro or a beginner, embracing the use of dovetail jigs can elevate your woodworking projects and enhance your overall skill set. So, grab a jig and start crafting!