The torque wrench is one of the most critical tools in mechanics and engineering, playing a vital role in ensuring the proper tightening of nuts and bolts. Its invention in the early 20th century marked a significant milestone in industrial history, as it enabled engineers and mechanics to apply precise amounts of torque, ensuring machinery and structures operated efficiently and safely. While modern torque wrenches have evolved with digital technologies, the vintage torque wrench holds a special place in mechanical tool history.

The Invention of the Torque Wrench: A Game-Changer in Engineering

The torque wrench was invented in 1918 by Conrad Bahr, an American engineer who saw the growing need for precise fastening in an increasingly complex mechanical world. As machinery became more sophisticated, the need for exact torque specifications grew. Bahr’s torque wrench was designed to solve this problem by ensuring that bolts and nuts were tightened to the correct specifications, preventing equipment failure due to over-tightening or under-tightening.

Why Precision Was Critical in the Early 20th Century

The rise of automobiles, aviation, and industrial machinery made it essential to ensure that components were securely fastened without causing damage. Over-tightening could strip threads or break components, while under-tightening could lead to catastrophic failures. The torque wrench provided a way to apply just the right amount of force, allowing engineers to meet strict safety standards and improve overall performance.

Bahr’s invention was initially a simple mechanical tool, but it quickly became indispensable in industries such as automotive repair, aerospace, and construction. The torque wrench allowed mechanics to apply force with greater control, which was crucial in maintaining the integrity of machines that were growing in both power and complexity.

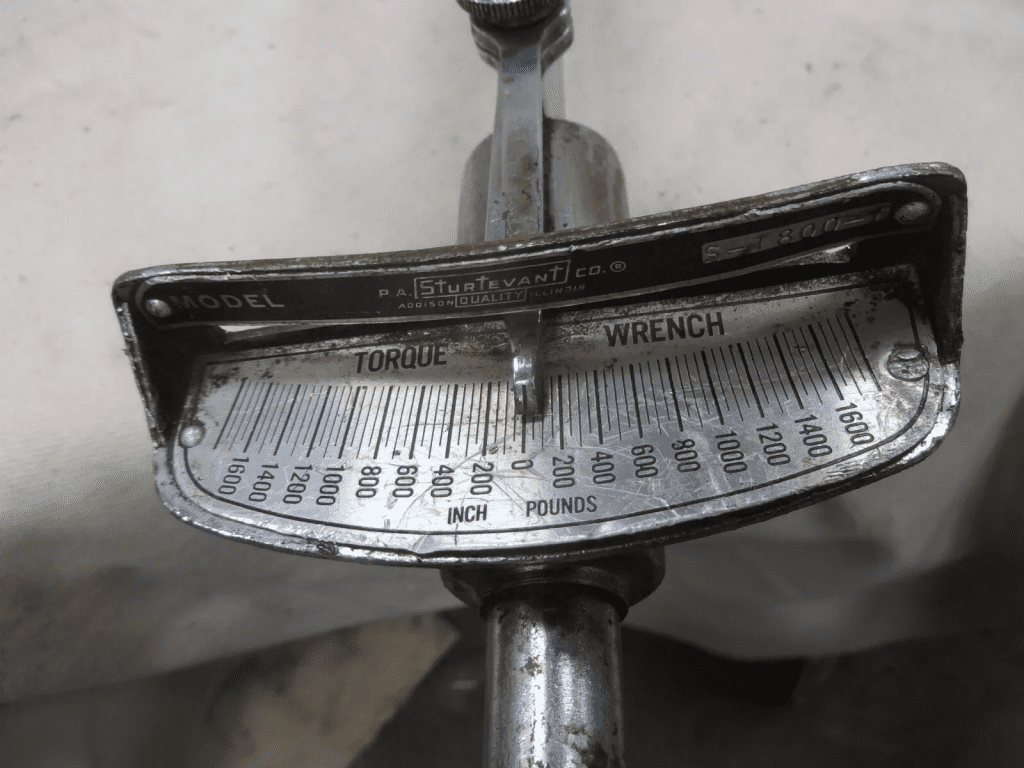

How the Vintage Torque Wrench Worked: Simplicity Meets Precision

Early torque wrenches were relatively straightforward devices. The vintage models primarily came in two types: beam torque wrenches and spring torque wrenches. Both had distinct mechanisms to measure and apply torque, but they shared the common goal of ensuring precise fastening.

Beam-Type Torque Wrenches

The beam-type wrench was one of the first designs. It featured a long, flexible beam that would bend as torque was applied. A scale and pointer attached to the wrench allowed the user to see how much torque was being exerted. While simple, it required a steady hand and careful observation to get an accurate reading. The advantage of the beam wrench was that it didn’t need recalibration, making it a reliable tool for many mechanics.

Spring-Type Torque Wrenches

The spring-type wrench, also known as the deflecting beam wrench, used a calibrated spring mechanism to measure torque. As torque was applied, the spring would compress or stretch, depending on the design. These wrenches had an internal scale that showed the amount of torque being applied. While more sophisticated than the beam-type wrench, they required regular calibration to maintain accuracy.

Both types of vintage torque wrenches had to be manually adjusted and calibrated, which made them less convenient than today’s digital models. However, for the time, they provided an unmatched level of control and precision.

Industrial Applications: Torque Wrenches Across Key Sectors

The torque wrench became a staple in several industries due to its ability to ensure the safe and efficient operation of mechanical systems. Its usage extended across automotive, aerospace, manufacturing, and construction, where the need for precise tightening of bolts was paramount.

In the Automotive Industry

The torque wrench quickly gained traction in the automotive sector. Cars and trucks depended on properly fastened components to operate safely. Engines, suspensions, and wheels needed exact torque measurements to function correctly, and torque wrenches became a standard tool in repair shops and assembly lines. They ensured that parts like cylinder heads, wheel bolts, and engine components were tightened to the manufacturer’s exact specifications, preventing both engine failure and accidents.

In Aerospace and Aviation

In aerospace, where safety is critical, the torque wrench became indispensable. Aircraft components, such as landing gear and engine parts, required extremely precise fastening to withstand the intense pressures of flight. Even a slight error in torque could lead to dangerous situations. Vintage torque wrenches were commonly used to assemble and maintain aircraft, helping to ensure both safety and performance.

In Construction and Structural Engineering

Torque wrenches were also used in structural applications, where the integrity of large-scale buildings, bridges, and towers relied on precise fastening. Bolts used in steel frameworks or mechanical joints needed to be tightened accurately to ensure the stability of the structure.

The Enduring Legacy of the Vintage Torque Wrench

The invention of the torque wrench marked a revolution in precision engineering. Although technological advancements have introduced more sophisticated and automated versions of the tool, the vintage torque wrench remains a beloved item among collectors, hobbyists, and even some mechanics.

Collectors and Enthusiasts

Today, vintage torque wrenches are cherished by tool collectors and mechanical history enthusiasts. These early models symbolize the ingenuity and craftsmanship of the time. Their simple yet effective design captures the spirit of early 20th-century engineering, a time when hands-on expertise was essential to ensuring the functionality of mechanical systems. Collectors value these tools not only for their historical significance but also for their rugged durability and timeless design.

Influence on Modern Torque Measurement Tools

The impact of the vintage torque wrench is still seen in modern engineering. While today’s torque wrenches are often digital and offer automatic settings, they owe their existence to the mechanical principles established by early wrenches. The fundamental concept of applying precise torque remains the same, whether the tool is operated manually or digitally.

The Shift to Click-Type and Digital Wrenches

Modern torque wrenches, such as click-type and digital models, offer greater convenience and accuracy, but their core functionality is rooted in the original invention. The click-type wrench, which provides an audible click when the desired torque is reached, and digital versions with LED displays are direct descendants of the beam and spring-type designs.

Conclusion: A Tool That Defined an Era of Precision

The vintage torque wrench stands as a testament to the evolution of mechanical tools and the quest for precision in engineering. From its humble beginnings as a manual tool invented by Conrad Bahr in 1918, the torque wrench became an essential device across industries, ensuring the safety, performance, and longevity of countless mechanical systems.

While modern versions have taken over with digital innovations and automated processes, the vintage torque wrench continues to inspire tool design and holds a place of honor among collectors and mechanics. Its legacy is a reminder of a time when precision and craftsmanship were at the forefront of industrial progress, a time when a simple tool revolutionized the way the world tightened its bolts.