In the world of precision measurement, the micrometer stands as one of the most influential tools ever developed. Originally created to solve the challenges of measuring small dimensions with accuracy, the micrometer has evolved over time to become a symbol of engineering ingenuity. Let’s explore the fascinating history of this revolutionary tool, its usage, and its enduring legacy in modern manufacturing and engineering.

The Invention of the Micrometer: A Game-Changer in Measurement

The micrometer, often referred to as the micrometer screw gauge, traces its origins to the early 19th century. The invention is credited to Jean Laurent Rixens, a French inventor who patented the first micrometer in 1829. At the time, engineers and machinists struggled to measure small dimensions with the available tools. Rixens’ device provided a groundbreaking solution by allowing for precise measurements that were previously unattainable.

Initially, the micrometer was welcomed in the fields of mechanical engineering and manufacturing, where the need for exact dimensions in parts was crucial to maintaining quality and ensuring proper functionality. Over the years, Rixens’ original design has been refined and improved, making it even more accurate and user-friendly. Early models of the micrometer featured mechanical advancements such as vernier scales and the use of high-quality materials that enhanced both the durability and precision of the tool.

Evolution and Adoption of the Micrometer

As the industrial revolution continued to unfold in the 19th and early 20th centuries, the demand for more precise tools surged. The micrometer’s design evolved to meet the growing needs of industries ranging from automotive to aerospace. With its ability to measure extremely small increments—often down to micrometers (millionths of a meter)—the micrometer became indispensable in industries requiring exact tolerances.

One of the key improvements made to the micrometer over time was the introduction of the vernier scale. This addition allowed users to read measurements even more accurately, down to fractions of a millimeter or inch. Manufacturers began producing micrometers with various specialized functions, such as models designed specifically for measuring internal dimensions, external diameters, or depths. Each variation was tailored to different industrial needs, making the micrometer an essential part of toolkits in various sectors.

The Vintage Micrometer Machinist Tool: How It Works

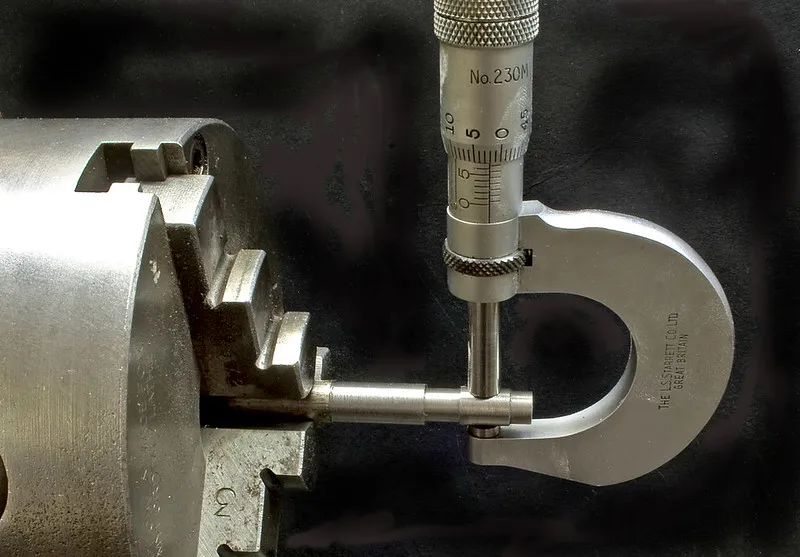

The vintage micrometer machinist tool operates on a simple yet highly effective screw mechanism. The tool typically consists of several key components: a calibrated screw, a spindle, and an anvil. The object to be measured is placed between the anvil and the spindle. By turning the screw, the spindle moves closer to or further away from the anvil, allowing the object to be gently compressed for measurement.

This screw mechanism is what gives the micrometer its incredible precision. Each turn of the screw corresponds to a set increment on the calibrated scale, meaning that even the smallest movements result in highly accurate measurements. This design allows machinists and engineers to measure the thickness of materials, the diameter of small objects, and the distance between surfaces with extreme precision. The micrometer’s ability to measure in microns or mils (thousandths of an inch) made it the go-to tool for industries where every fraction of a millimeter counts.

Micrometers in Action: Precision Across Industries

Throughout its history, the micrometer has found use in an astonishing array of industries. In the automotive sector, for instance, precise measurements are essential for engine parts, transmission components, and other mechanical systems. Similarly, in the aerospace industry, even the smallest variance in the dimensions of parts could lead to disastrous consequences, making micrometers critical for quality control.

One of the areas where micrometers have had the most significant impact is in precision engineering. From delicate clock mechanisms to cutting-edge electronics, micrometers have been used to ensure that components are manufactured to the tightest tolerances. In fact, the introduction of the micrometer is often credited with enabling advancements in technology by allowing for the development of smaller, more intricate parts.

The Legacy of the Vintage Micrometer: A Testament to Craftsmanship

Before the digital age brought about electronic measuring devices, the vintage micrometer was a cornerstone of quality control and mechanical precision. The legacy of this remarkable tool is not just in its functionality but in what it represents: precision engineering at its finest.

Even as modern tools have largely replaced manual micrometers in some industries, the classic vintage micrometer is still revered by collectors and enthusiasts. Many of these tools are now considered valuable artifacts, showcasing the craftsmanship of a bygone era. Vintage micrometers are often displayed in museums and featured in collections, serving as a reminder of the painstaking work and innovation that drove the evolution of measurement tools.

Today, many workshops still have a place for the vintage micrometer. Despite the advent of digital micrometers and laser-based measuring systems, the classic version of this tool is cherished for its simplicity and reliability. For machinists who value the tactile feedback and direct control that a manual micrometer provides, the vintage model remains a symbol of precision and craftsmanship.

Modern Advancements: From Analog to Digital Micrometers

While vintage micrometers continue to be prized for their historical significance, modern iterations of the tool have embraced digital technology. Digital micrometers offer several advantages over their analog counterparts, such as easy-to-read digital displays and the ability to quickly convert between metric and imperial measurements.

Moreover, electronic micrometers can store data and integrate with software systems, allowing engineers to streamline their workflow and improve efficiency. These advancements have made micrometers even more accessible and versatile in today’s fast-paced manufacturing environments.

However, no matter how advanced these tools become, the core principle behind the micrometer remains the same: the need for precision in measurement. Whether digital or analog, the micrometer’s role in ensuring the highest standards of quality in engineering and manufacturing remains as vital today as it was nearly two centuries ago.

Conclusion: The Micrometer’s Enduring Legacy in Precision Measurement

The micrometer has come a long way since Jean Laurent Rixens first patented his revolutionary design in 1829. From its early days as a breakthrough tool for machinists to its modern digital iterations, the micrometer continues to play a critical role in industries that demand accuracy and precision.

As a symbol of precision engineering, the vintage micrometer represents more than just a tool; it embodies the spirit of innovation that has driven technological progress for nearly two centuries. Whether displayed in museums or still actively used in workshops, the micrometer’s legacy endures as a testament to the power of human ingenuity and the timeless pursuit of perfection.